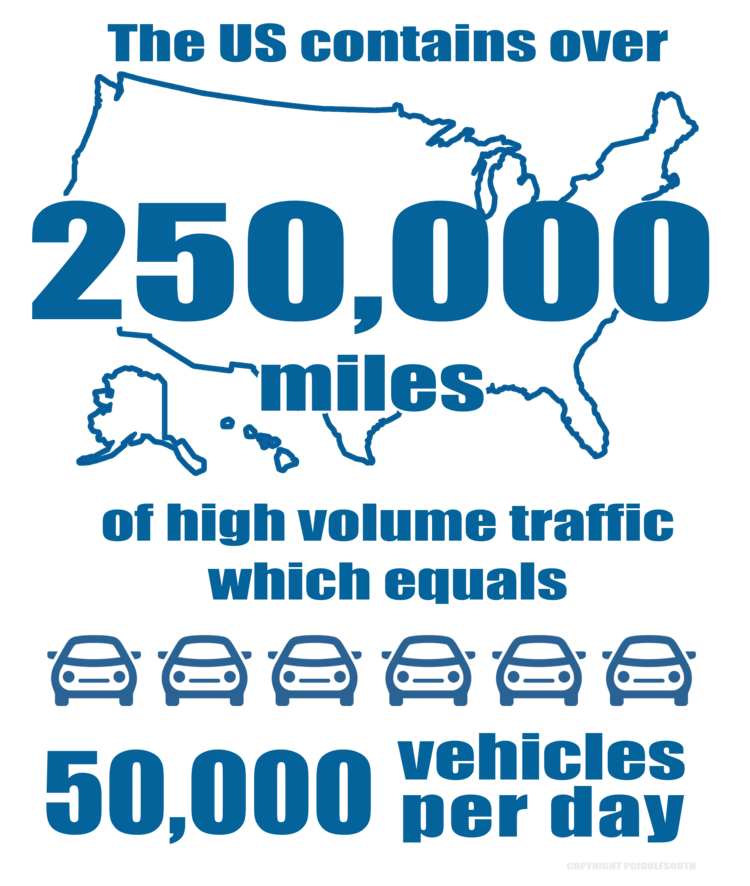

Having functioning transportation infrastructure like roads and bridges is vital to the nation. The US has over 4 million miles of roadways with 250,000 miles considered “high volume traffic”. Currently 20% of the roadways in the United States, and 10% of roadways in Florida, are considered in poor or mediocre condition that need repaving or other repairs. Traditional construction methods tend to cause congestion and slow down traffic on these roadways that see tens of thousands of vehicles every day. Precast pavement is a solution that helps keep traffic flowing and improve the life span of these roadways for the traveling public.

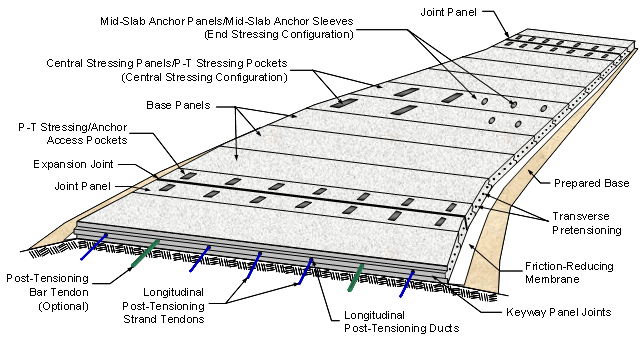

Prestressed Precast Concrete Panels (PPCP) can be designed to match the sizes of a one, two, or three lane highway. These panels are usually designed to be perpendicular to the center of the roadway and can include either one or both shoulders. Generally the precast pavement panels are pretensioned in the longer direction during manufacturing and then post-tensioned together in groups in the direction of traffic after installation so they act as one continuous slab. It is important that prestressing is provided in both directions in order to maximze the benefits of prestressing.

Through the use of precast concrete replacement slabs, improvements to I-5 North in Los Angeles, CA were made at night to minimize disruption.

Precast concrete pavement systems offer numerous benefits to the travelling public including:

Longer life span

A typical asphalt road surface has a lifespan of 10-15 years. A concrete road lasts 40 or more years.

Less maintenance

Concrete roads require less maintenance and have lower life-cycle costs over the service life of the roads

Quicker to construct

Concrete roads require less disruption to daily commuter traffic, need smaller work crews, and limited construction staging areas.